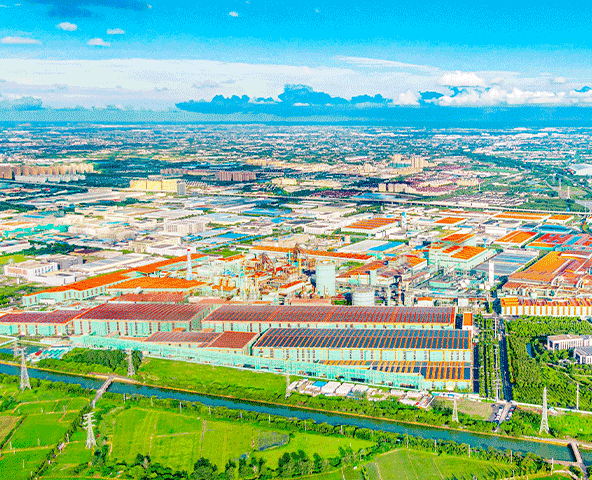

Industry Overview

Wind energy is one of the pollution-free energy sources, as a clean renewable energy, get more and more attention from all countries in the world.

Wind power has the advantages of clean, good environmental benefits, renewable, short infrastructure cycle and flexible installed scale. Wind power is an essential part of renewable energy development, an important force to promote energy technology progress and industrial upgrading, and an important measure to promote energy structure adjustment. China's wind power and other new energy power generation industries have very broad development prospects and are expected to maintain rapid development for a long time in the future.

-

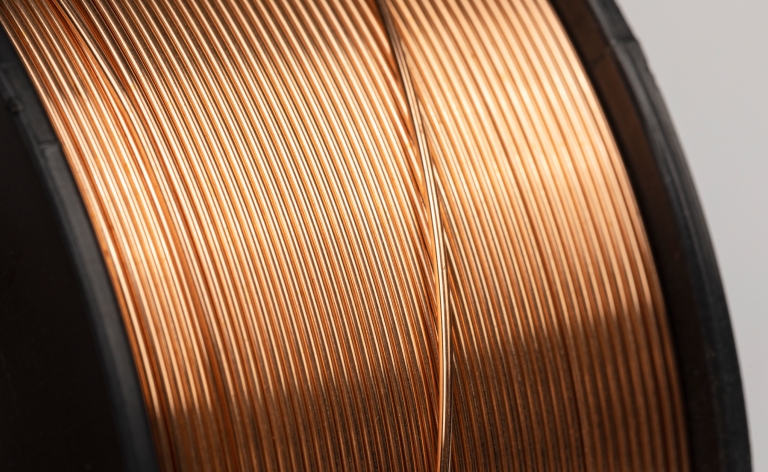

Bearing Steel Ball

-

Welding Materials

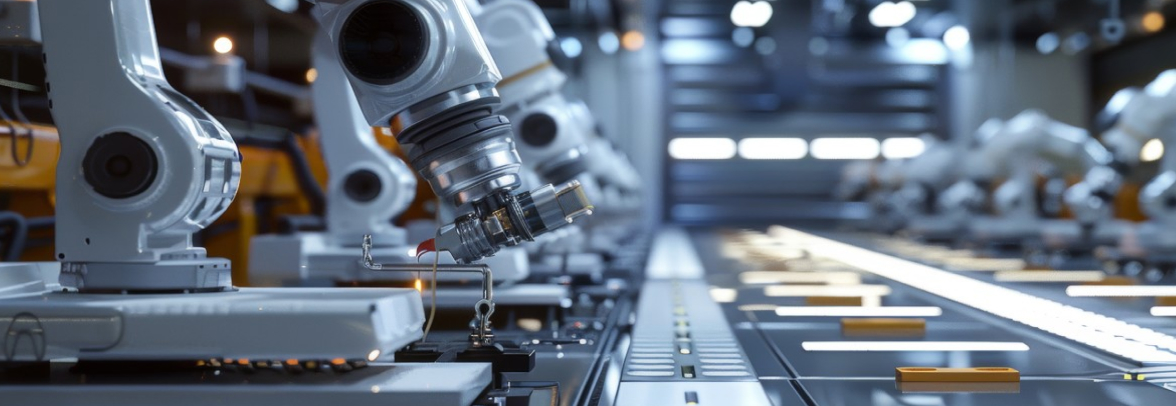

Product Application

Wind power generation uses wind to drive the windmill blades to rotate, and then uses a speed increaser to increase the rotation speed to prompt the generator to generate electricity. Slewing bearing is a new type of mechanical component that is gradually emerging around the world. It consists of inner and outer rings, rolling elements, etc., and is an important structure of wind turbines. Bearing steel ball products are used as rolling elements in yaw bearings of wind turbines and large slewing bearings of pitch bearings.

Research and Development

-

Wind power application research and development

Develop steel ball blanks for yaw and pitch bearings for 1.5~6MW wind turbines

-

Engineering machinery application research and development

Develop large-scale slew bearing steel ball blanks for engineering machinery.

-

Roller thermoforming technology

Develop hot forming technology for large rollers to replace turning rollers.

-

Net shaping forming

Research on near-net forming technology to compress the remaining volume of rolling element blanks and improve the yield rate.

-

Pre-heat treatment process

Independently develop the pre-heat treatment process for large bearing steel ball blanks, vigorously promote the application of controlled forging and controlled cooling technology, refine the grain and carbide particle sizes, and improve the contact fatigue life of bearing parts.

-

Wind power application research and development

Develop steel ball blanks for yaw and pitch bearings for 1.5~6MW wind turbines

-

Engineering machinery application research and development

Develop large-scale slew bearing steel ball blanks for engineering machinery.

-

Roller thermoforming technology

Develop hot forming technology for large rollers to replace turning rollers.

-

Net shaping forming

Research on near-net forming technology to compress the remaining volume of rolling element blanks and improve the yield rate.

-

Pre-heat treatment process

Independently develop the pre-heat treatment process for large bearing steel ball blanks, vigorously promote the application of controlled forging and controlled cooling technology, refine the grain and carbide particle sizes, and improve the contact fatigue life of bearing parts.

Product Certification

Be our partners

Longteng Special Steel actively seek industry cooperation, jointly promote industry progress and dev

Contact us

Please provide the following details so that our representatives can better understand your needs and get in touch with you as soon as possible.