Industry Overview

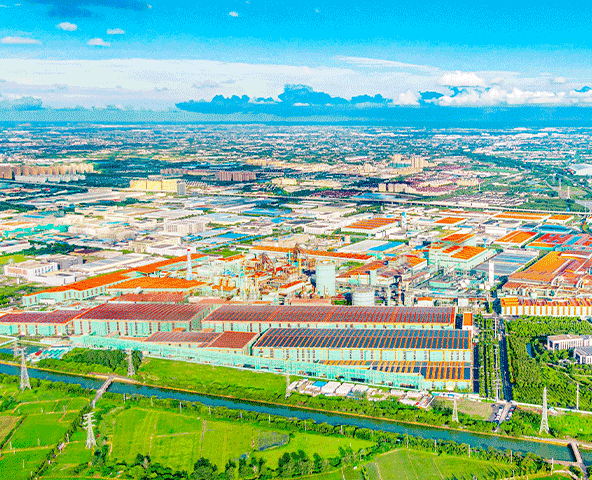

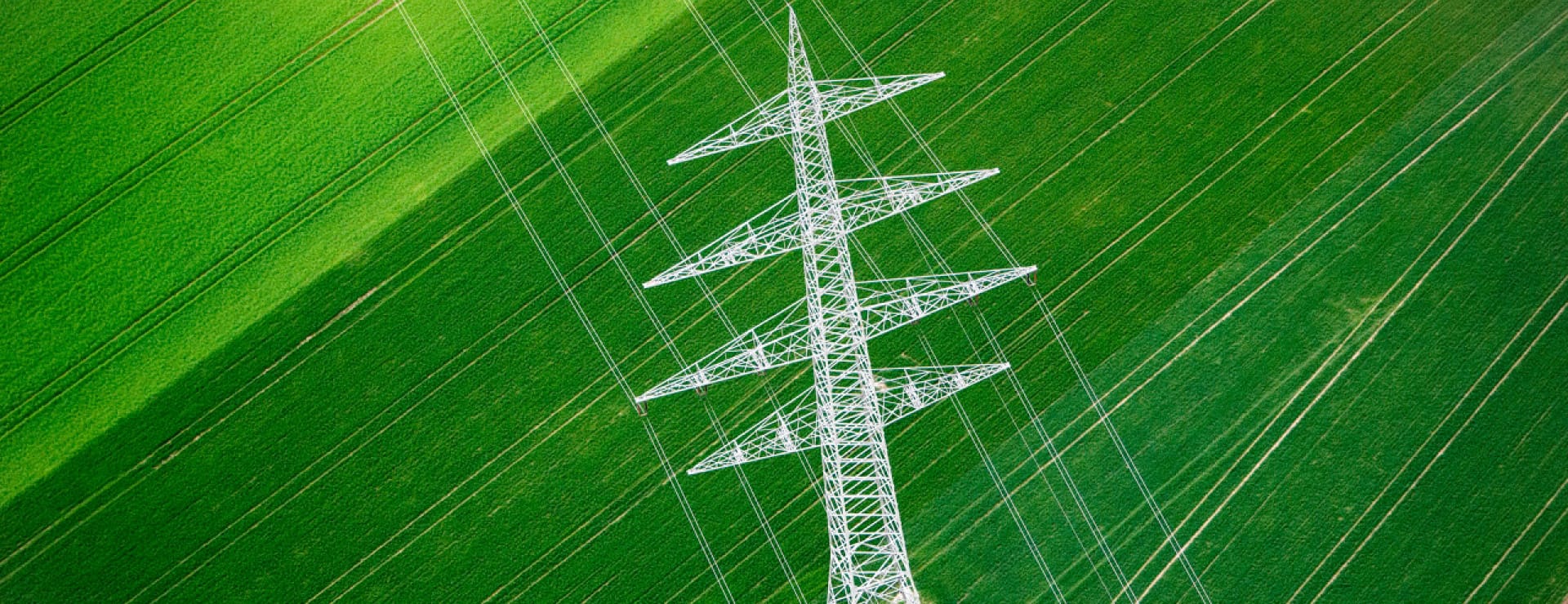

In recent years, with the rapid growth of the national economy, electricity consumption has soared, and the power industry has developed rapidly. The state vigorously promotes the "west power transmission to the East" and "North power transmission to the south" projects, especially the successful practice of UHVDC transmission projects, which has strongly promoted the rapid development of the power transmission industry. China's electric power transmission industry shows a good development trend, with the continuous increase of grid investment, the demand for electric power transmission will also increase, transmission line industry development prospects are broad.

-

Electric Angle Steel

-

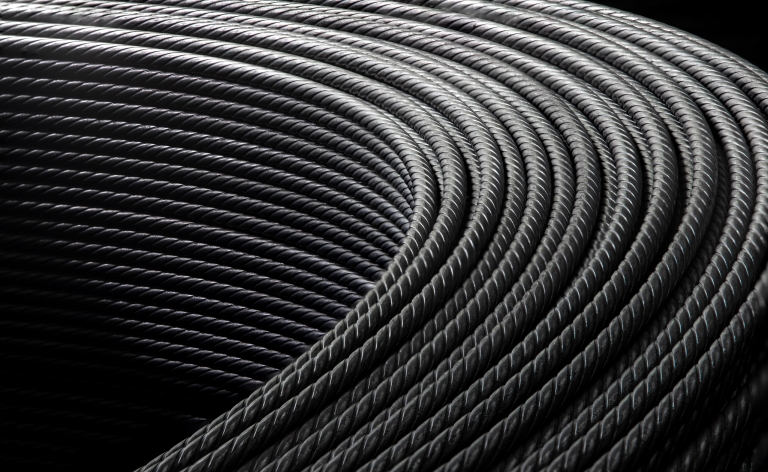

PC Steel Bar

Product Application

Angle steel is commonly known as Angle steel bar. Its section is a long strip of steel that is perpendicular to each other at right angles. Angle steel has good toughness, high strength, good corrosion resistance, welding performance and surface properties. Its main purpose is to make frame structure, such as high voltage transmission tower, etc. At present, the state vigorously promotes the high voltage transmission project, and the large size Angle steel has been widely used.

Steel rod for prestressed concrete (PC steel rod) has been widely used in prestressed components such as transmission line poles because of its high strength, toughness, low relaxation, strong grip with concrete, good weldability, upsettability, saving materials and other characteristics, and has a very broad market.

Research and Development

-

The development of ∠220 and ∠250 large size Angle steel

Was applied to the first ±800kv uhv direct current transmission project of "hami-zhengzhou" in china.

-

Double straightening + strong straightening

Double straightening + strong straightening is becoming perfect to ensure that the straightness accuracy of each Marine section steel is less than 1‰, reaching the international advanced level.

-

Unique chemical composition design

At one stroke, the yield strength of high-strength large-size Angle steel is easy to be low, and the steel has good impact toughness.

-

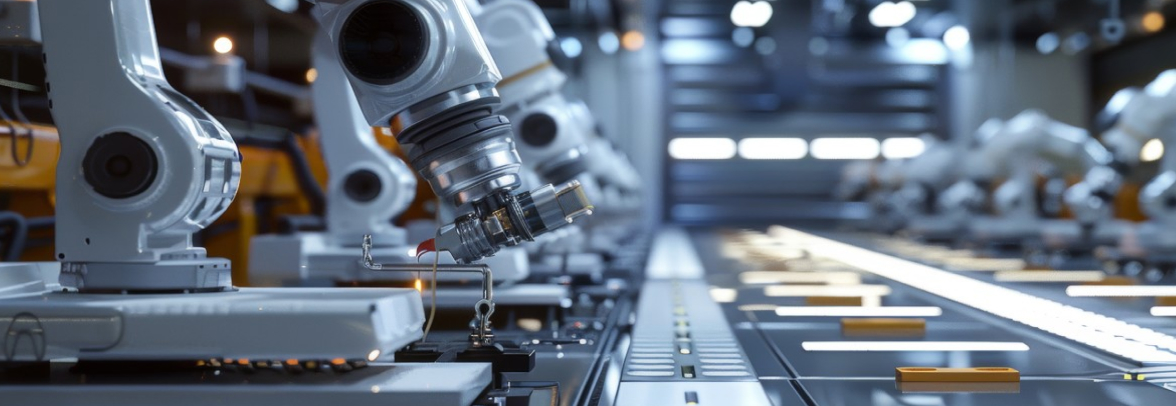

Energy saving and environmental protection auto production

The automatic production line is composed of online automatic straightening and rust removal, cold drawing and score, online heating by high-frequency induction heating furnace (secondary quenching heating and primary tempering heating), automatic control of cooling water temperature of heat treatment, water through heat treatment, online rust prevention treatment of finished products and SVG harmonic elimination + reactive power compensation and other advanced technology and equipment. Realize the mode of energy saving and environmental protection automatic production; At the same time, ensure the product quality to reach the domestic advanced level.

-

Research and Development

Customers have a large pipe diameter in the production of sea piles, generally 800-1200mm, and the largest one even reaches 1500mm. Therefore, when customers choose prestressed steel rods, they require steel rods to reach 14mm or above. Through the full cooperation of all departments of the branch, samples have been produced for customer trial.

-

Cooperative research and development

Cooperate with State Grid to develop low temperature resistant high strength Angle steel.

-

Automatic spray anti-rust paint

Developed anti-rust products in rainy season.

-

The development of ∠220 and ∠250 large size Angle steel

Was applied to the first ±800kv uhv direct current transmission project of "hami-zhengzhou" in china.

-

Double straightening + strong straightening

Double straightening + strong straightening is becoming perfect to ensure that the straightness accuracy of each Marine section steel is less than 1‰, reaching the international advanced level.

-

Unique chemical composition design

At one stroke, the yield strength of high-strength large-size Angle steel is easy to be low, and the steel has good impact toughness.

-

Energy saving and environmental protection auto production

The automatic production line is composed of online automatic straightening and rust removal, cold drawing and score, online heating by high-frequency induction heating furnace (secondary quenching heating and primary tempering heating), automatic control of cooling water temperature of heat treatment, water through heat treatment, online rust prevention treatment of finished products and SVG harmonic elimination + reactive power compensation and other advanced technology and equipment. Realize the mode of energy saving and environmental protection automatic production; At the same time, ensure the product quality to reach the domestic advanced level.

-

Research and Development

Customers have a large pipe diameter in the production of sea piles, generally 800-1200mm, and the largest one even reaches 1500mm. Therefore, when customers choose prestressed steel rods, they require steel rods to reach 14mm or above. Through the full cooperation of all departments of the branch, samples have been produced for customer trial.

-

Cooperative research and development

Cooperate with State Grid to develop low temperature resistant high strength Angle steel.

-

Automatic spray anti-rust paint

Developed anti-rust products in rainy season.

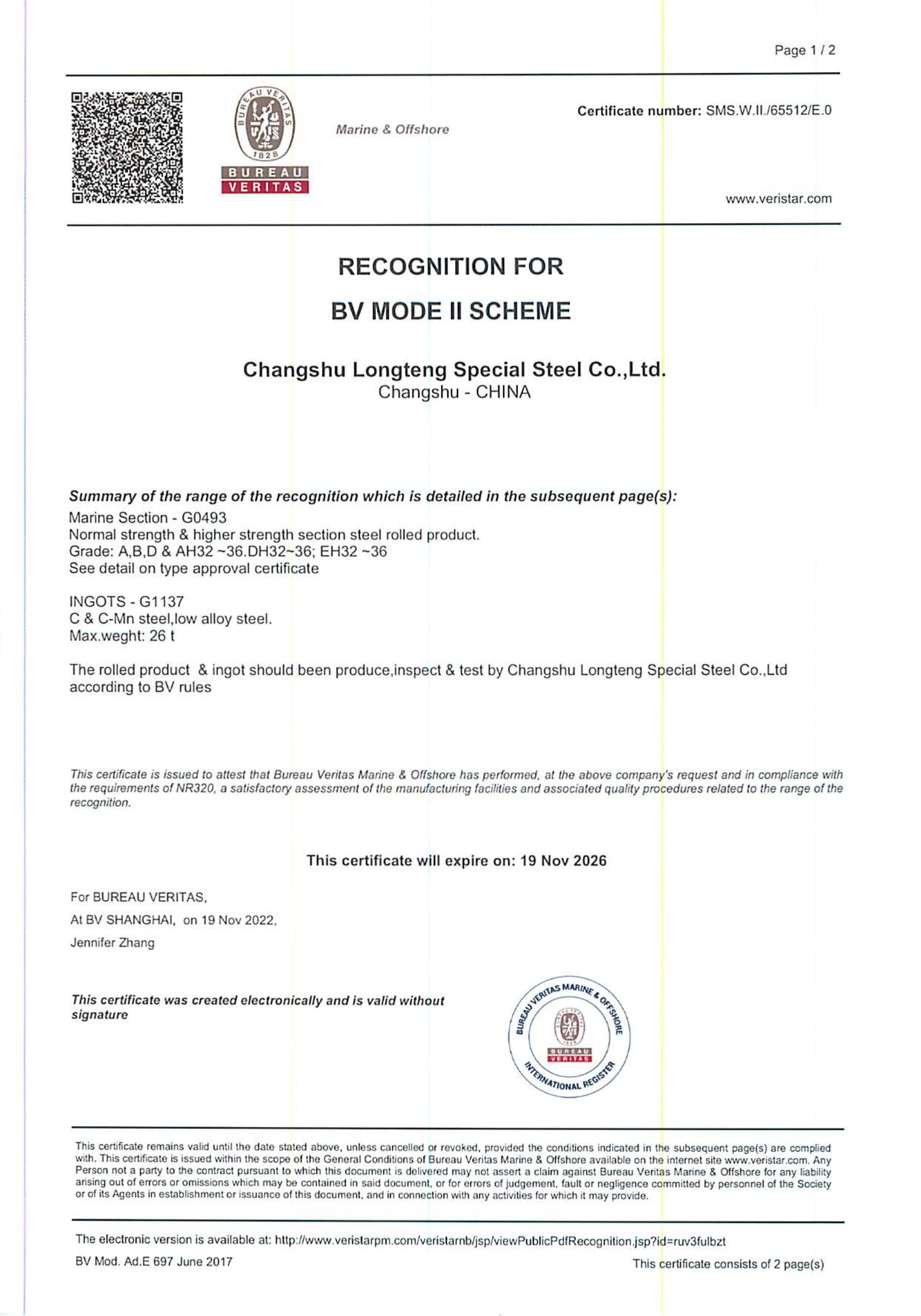

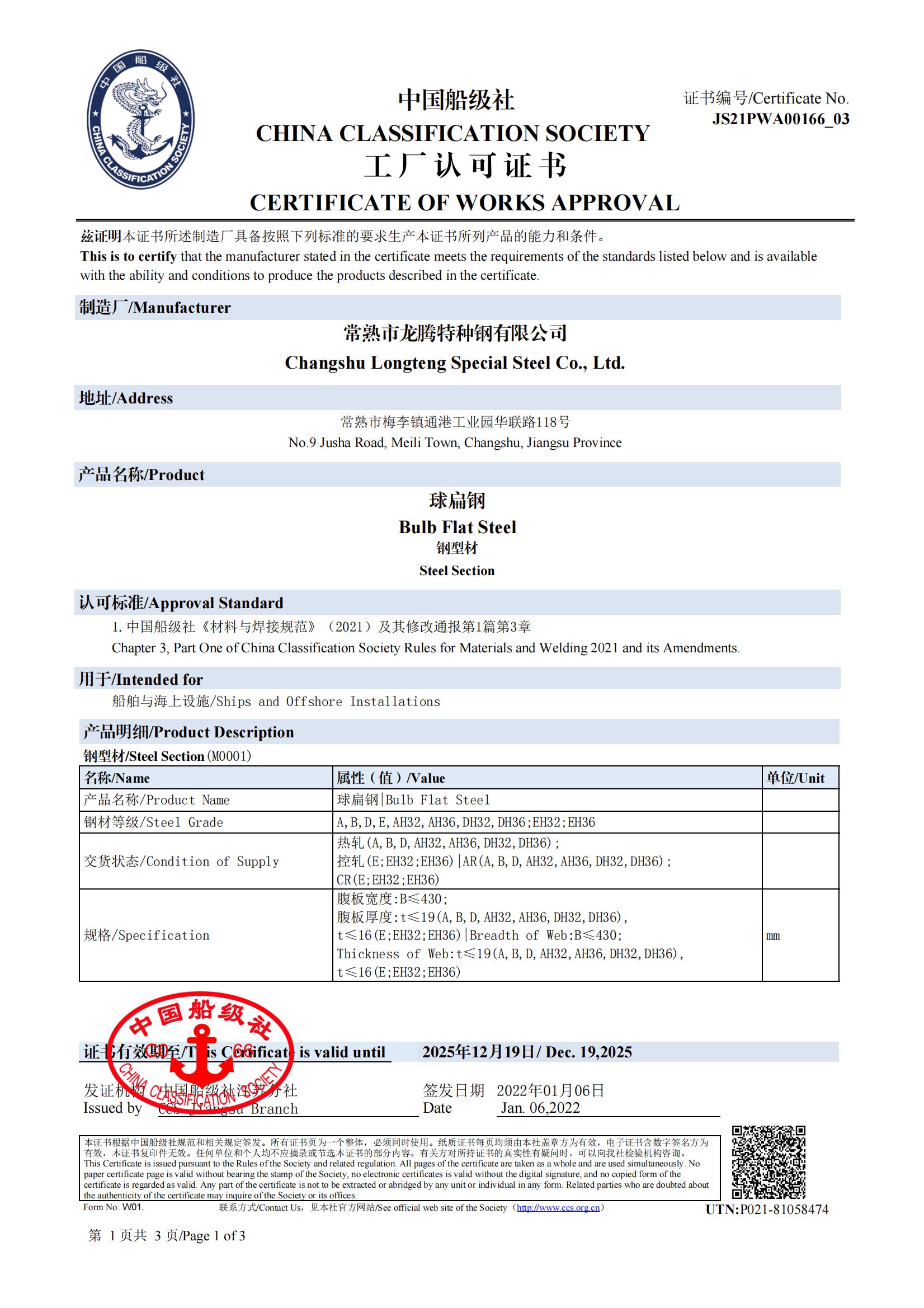

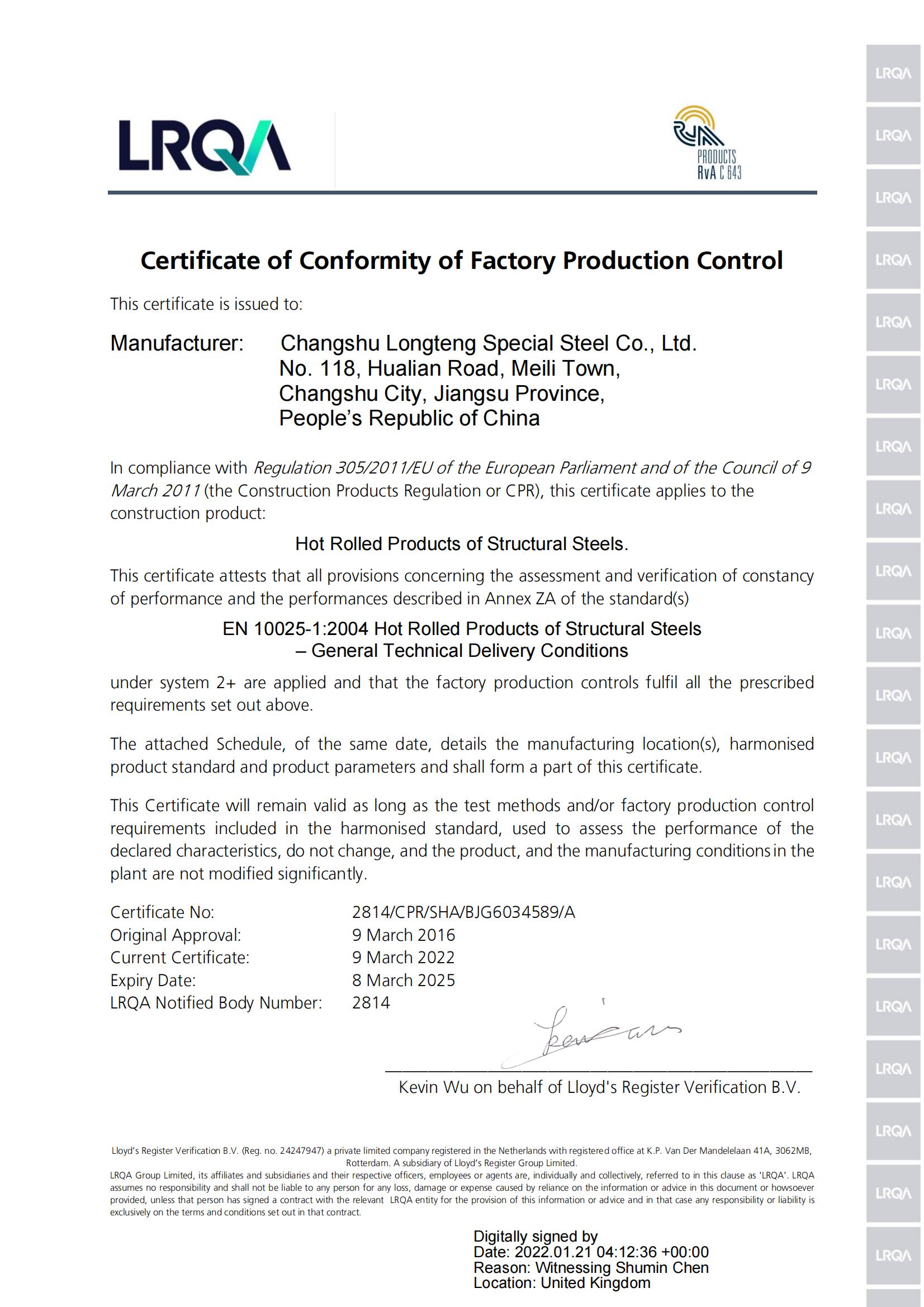

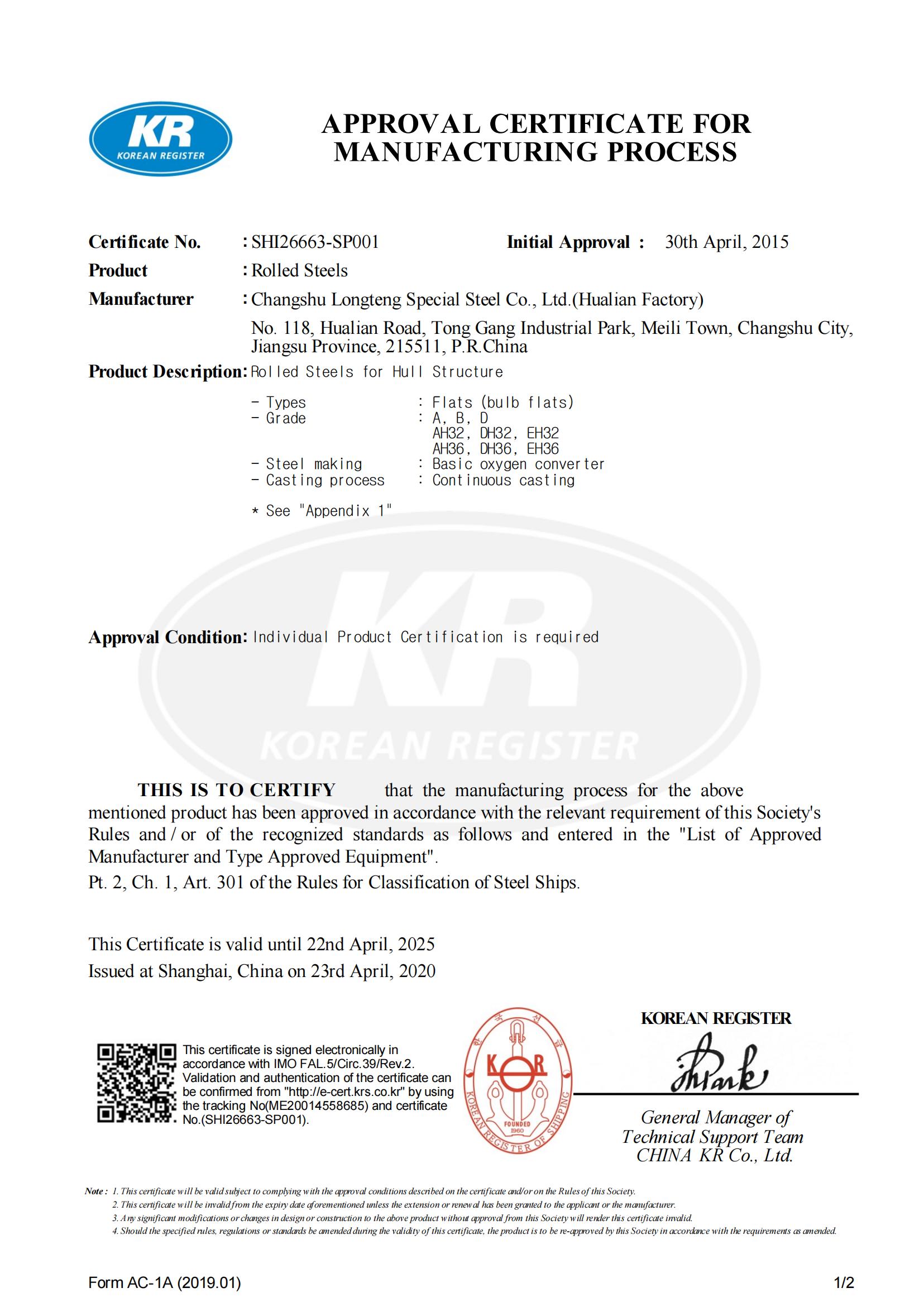

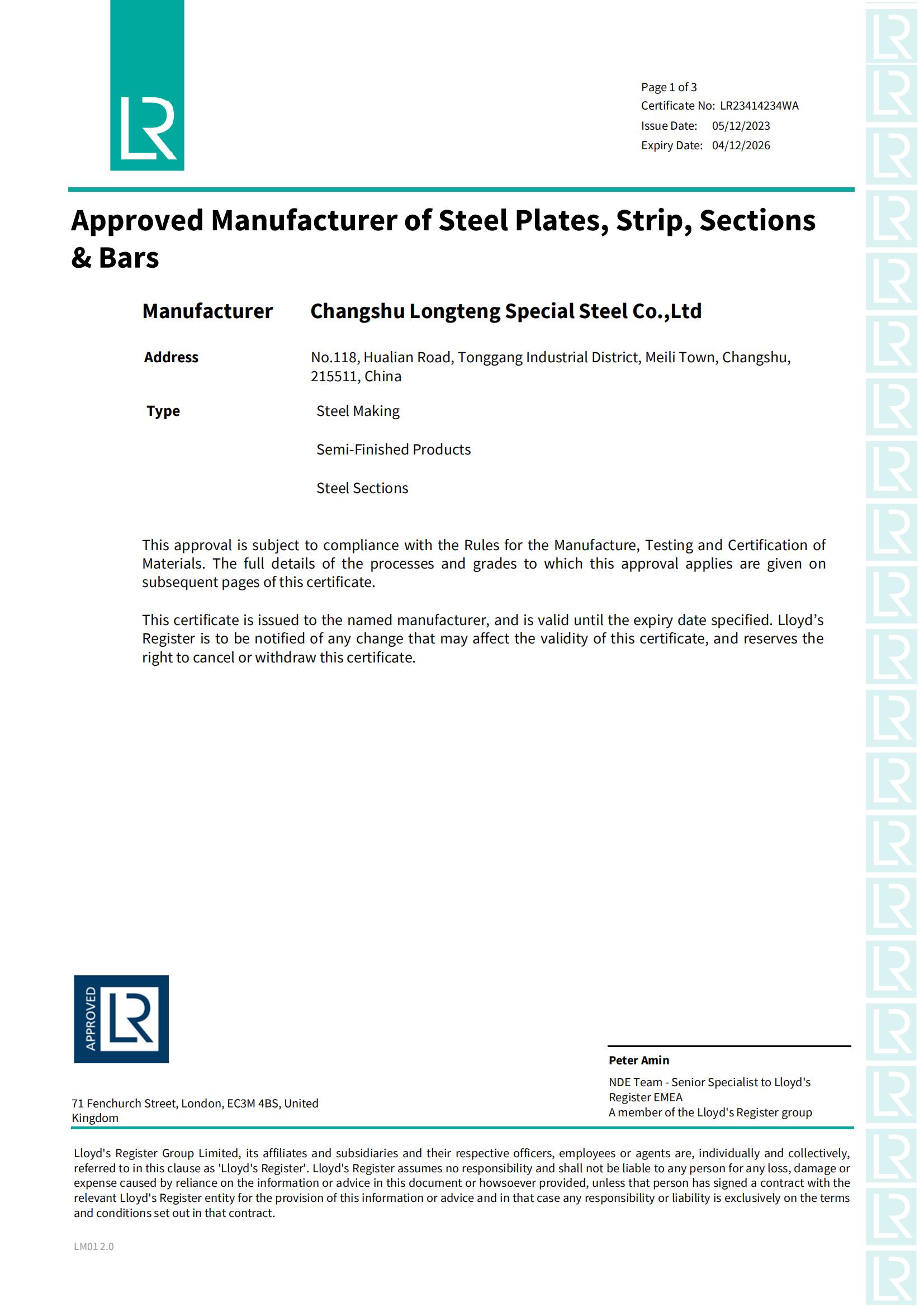

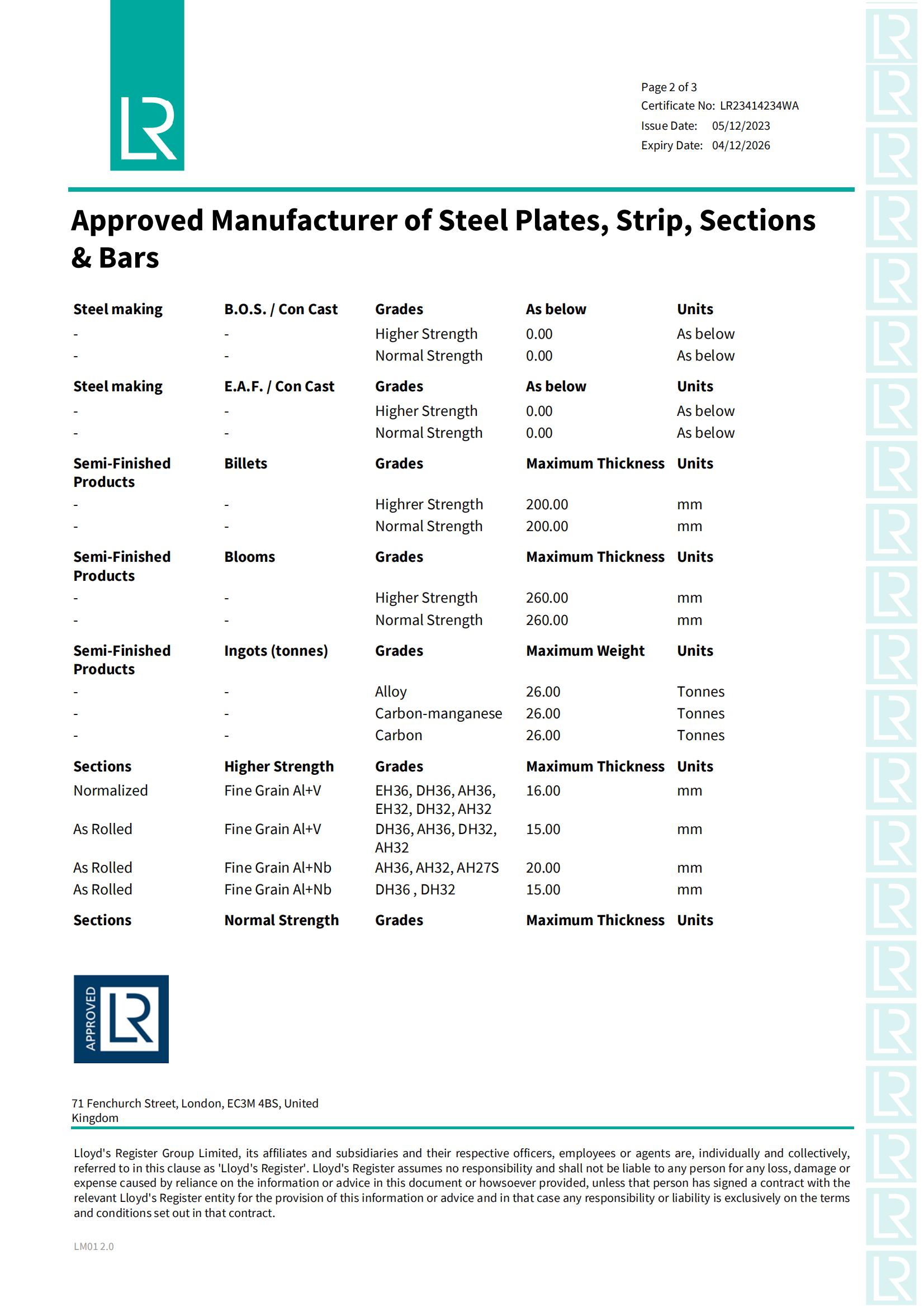

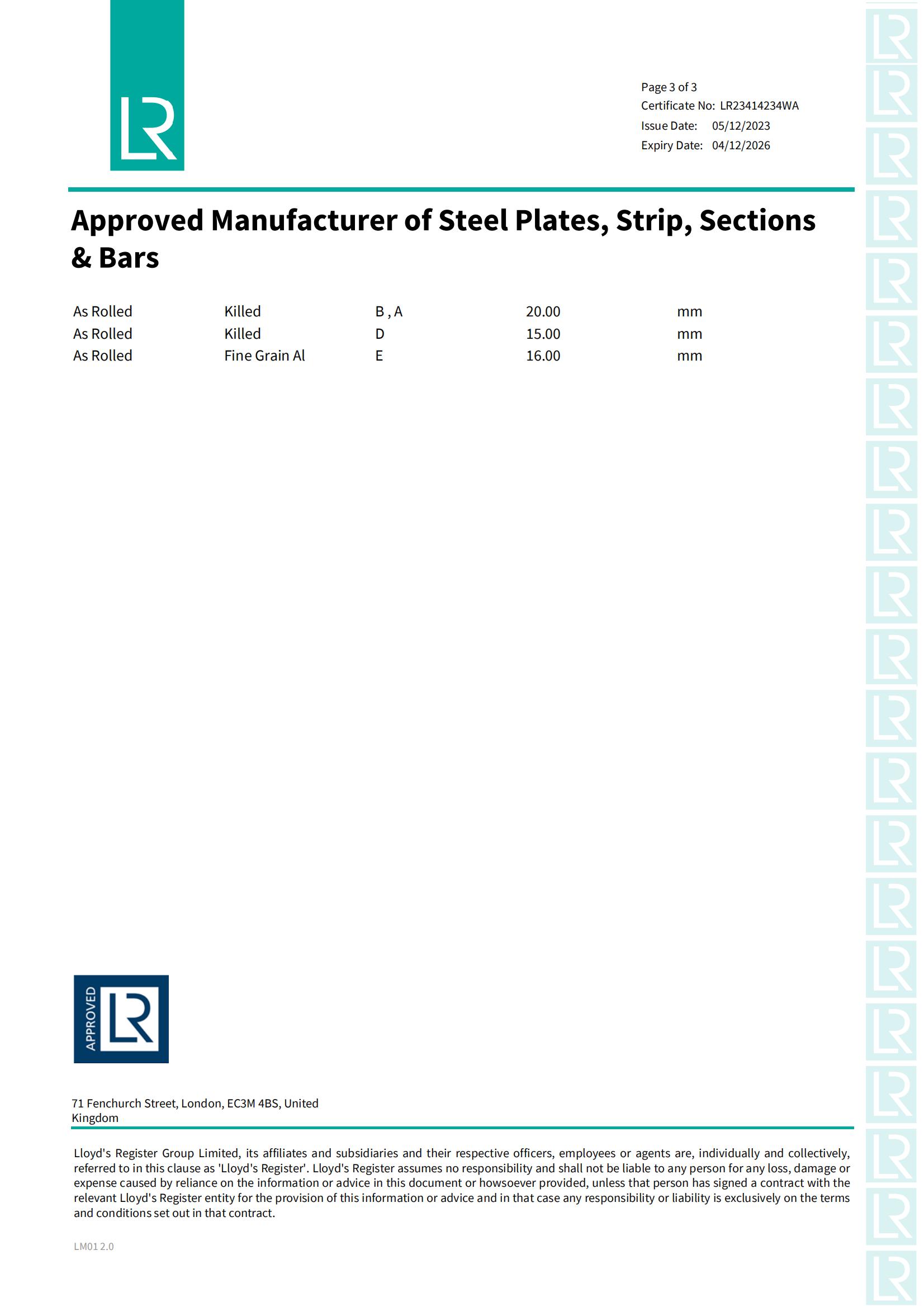

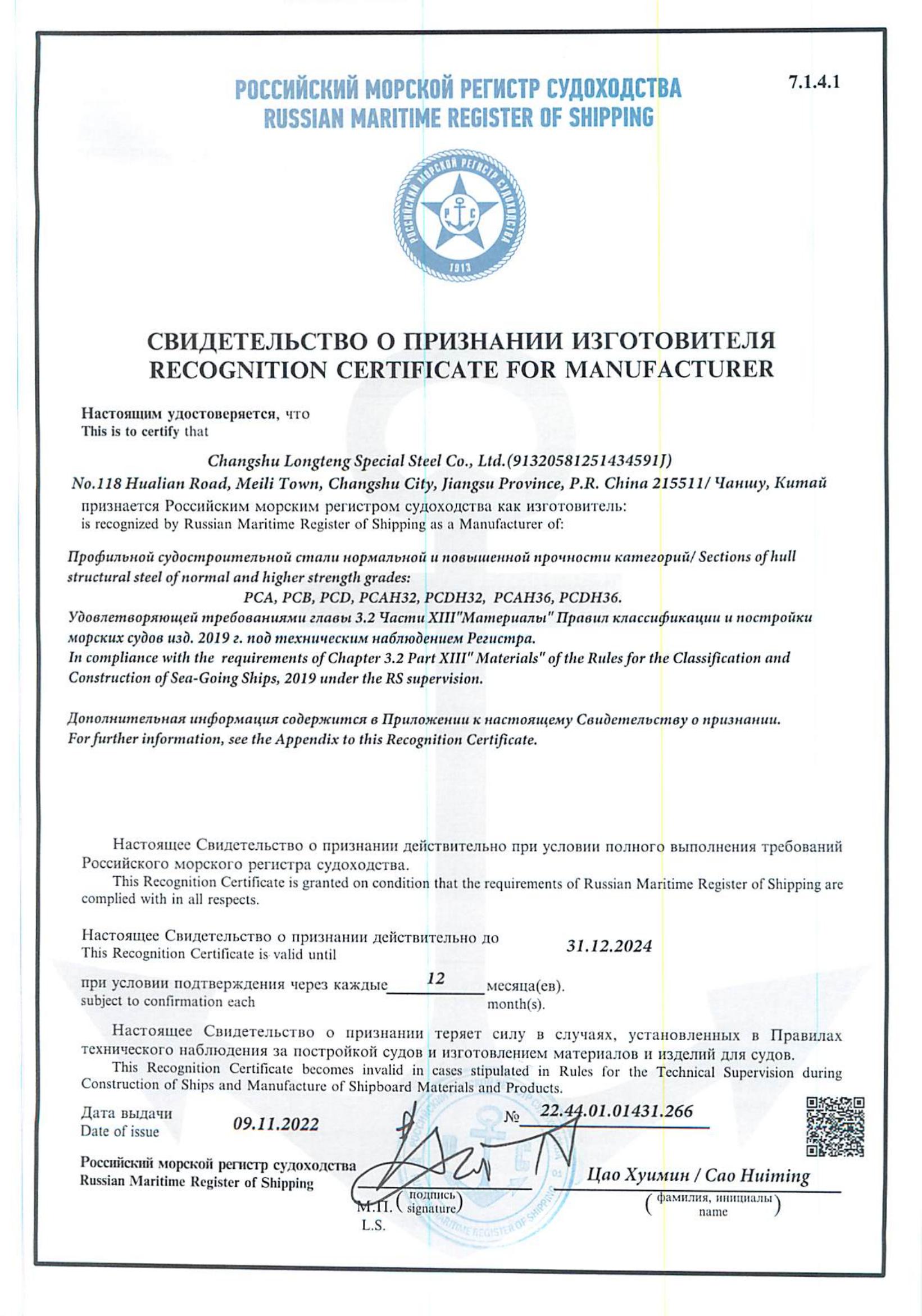

Product Certification

Contact us

Please provide the following details so that our representatives can better understand your needs and get in touch with you as soon as possible.