Industry Overview

From the brilliant light of the Bronze Age to the stirring sound of the industrial revolution, the development process of metallurgical mines embodies the endless sweat and wisdom of human beings. We have mined precious minerals from the depths of the Earth and turned them into a powerful driving force for society to move forward. In the face of the challenges and opportunities brought by globalization, metallurgical mines are developing and reforming at an unprecedented speed, and green, low-carbon and sustainable production mode has become a new development trend.

-

Hot olled and hot forged wear-resistant steel balls

Product Application

Grinding steel ball for steel grinding machine (referred to as grinding ball) is widely used in large non-ferrous metal mines such as gold mine, nickel mine and copper mine, ferrous metal mine such as iron mine and precious metal processing industry such as metallurgy and chemical industry at home and abroad, used for ball mill and semi-automatic mill to crush ore. With the characteristics of high hardness, low breakage rate and excellent wear, it is favored by users all over the world.

Research and Development

-

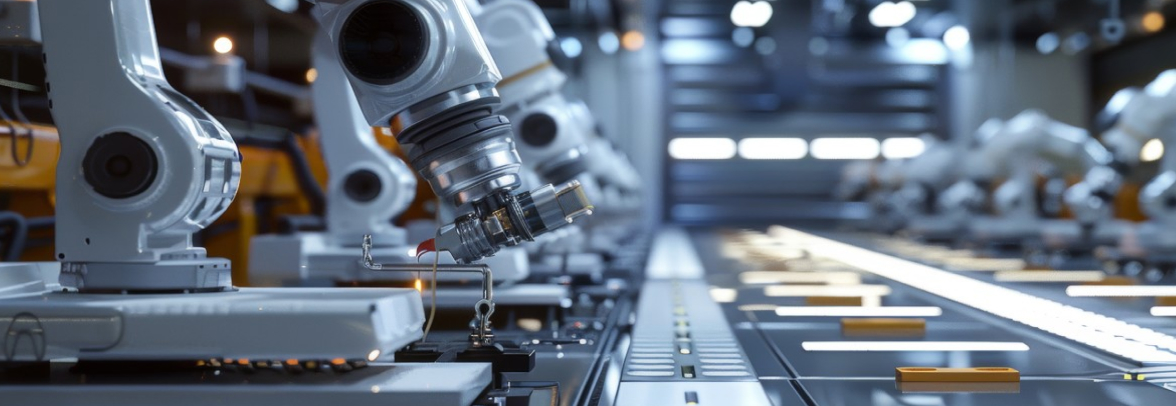

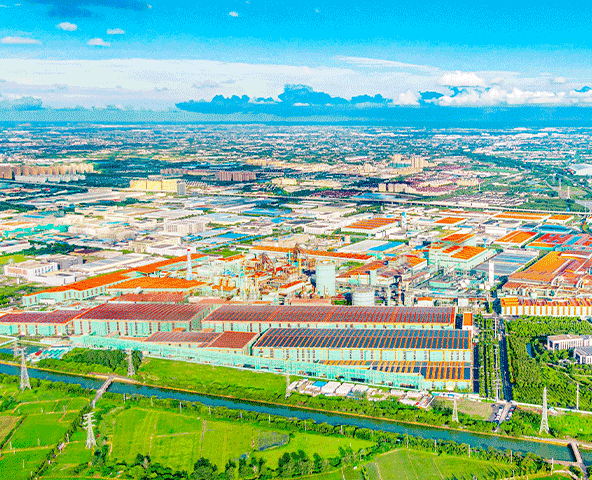

Production line

Grinding ball branch has 4 international advanced production lines, 7 industry advanced automatic continuous rolling production lines, 11 professional forging ball production lines, covering all specifications of large, medium and small.

-

Pre-heat treatment process

Independent research and development of large steel ball pre-heat treatment process.

-

Proprietary grinding assist System FIT System

The use of high precision automation control with strategic partners supporting equipment, the implementation of proprietary grinding auxiliary System FIT System.

-

Independent R&D

Designed 6 inch and 6.25 inch steel balls with high hardness to make a positive contribution to the field of semi-automill grinding applications in mines worldwide.

-

Method of adding balls

Independently developed semi-self-grinding "space-time dynamic ball adding method" and ball mill "space-time delay ball adding method", help to reduce ball consumption and power consumption, to achieve cost reduction and efficiency increase.

-

Production line

Grinding ball branch has 4 international advanced production lines, 7 industry advanced automatic continuous rolling production lines, 11 professional forging ball production lines, covering all specifications of large, medium and small.

-

Pre-heat treatment process

Independent research and development of large steel ball pre-heat treatment process.

-

Proprietary grinding assist System FIT System

The use of high precision automation control with strategic partners supporting equipment, the implementation of proprietary grinding auxiliary System FIT System.

-

Independent R&D

Designed 6 inch and 6.25 inch steel balls with high hardness to make a positive contribution to the field of semi-automill grinding applications in mines worldwide.

-

Method of adding balls

Independently developed semi-self-grinding "space-time dynamic ball adding method" and ball mill "space-time delay ball adding method", help to reduce ball consumption and power consumption, to achieve cost reduction and efficiency increase.

Product Certification

Be our partners

Longteng Special Steel actively seek industry cooperation, jointly promote industry progress and dev

Contact us

Please provide the following details so that our representatives can better understand your needs and get in touch with you as soon as possible.